Home >> PRODUCTS >> Ta&Nb Tubes/Rods/Wire >> Niobium Tube

|

|

Introduction:

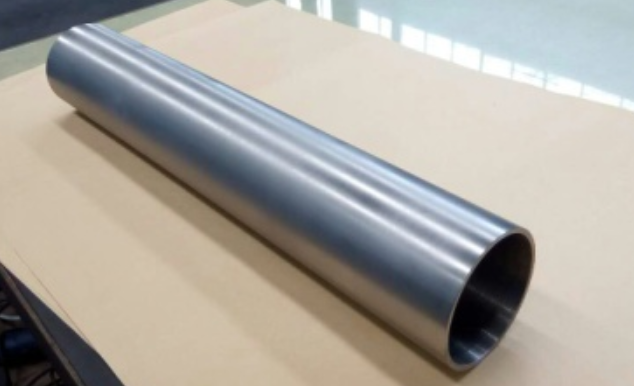

Niobium Welded Tubing /Tube/ Pipe, Purity 99.9%(3N) , ASTM B394-98

Application: To be used for manufacturing high sodium lamps, aerospace and aviation industry, structural material for engine, reactor for chemistry, heat exchanger tube, built-in component of reactor and coating material.

Specifications Grade:RO4200, RO4210 Purity: 99.9%(3N) Surface: tube wall should be smooth, clean, greaseless, without fissure or burr, no no oxidation or hydrogenation, no scratch or transformation

Metallic impurities, ppm max by weight, Balance – Niobium

Non-Metallic impurities, ppm max by weight

Mechanical properties for annealed tube/pipe,

Description We produce R04200, R04210 seamless tubes/pipes, welded tubes/pipes, capillary tubes which meet ASTM B 394-98 standard and the sizes can be customized as per your required dimensions. We will do our best to fulfill customers' needs and markets' demands by providing a great variety of customized products. Taking advantages of our high quality niobium oxide raw material, advanced equipment, innovative technology, professional team, we tailored your required products. You may tell us all your requirements and we dedicated in manufacturing upon your needs.

Niobium tubes are manufactured by ASTM B391 niobium ingots through annealing, cold rolling, cold drawing technology. We smelt the high purity Nb2O5 we sourcing from the Chinese biggest hydrometallurgy plant by means of aluminothermic reduction to produce niobium aluminum alloy. Then the niobium aluminum alloy will be smelted in high Vacuum EB furnace to produce niobium bars with Nb content 99% up, which will be smelted again in high Vacuum EB furnace to be purified and produce Niobium ingots with purity 99.9% up. The size can be tailored by the customers’ requirements. We control our products quality through the raw material source till the whole production line and finally deliver to our customers in order to make sure you purchase our products with stable and same quality for each lot. Our QC control our products quality through the raw material source till the whole production line and finally deliver to our customers in order to make sure you purchase our products with stable and same quality for each lot. They use Metallographic microscope, Hand-held X ray Fluorescence, Electronic tensile testing machine etc. instruments and tensile test to inspect the material and products and issue the COA for each lot. We have been certified by ISO9001:2015.

We are trying our best to innovate our techniques, enhance the product quality, increase the product utilization rate, lower down the costs, improve our service to supply our customers’ with higher quality products but lower purchase costs. Once you choose us, you will obtain our stable high quality products, more competitive price than other suppliers and our timely, high efficient services. |